|

QIHE GAOXIN HAOYU CNC MACHINERY CO., LTD

|

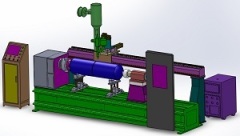

Highly Efficient Automatic Automaitc Fuel Tank Welding Machine

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

I. Design Mission

1.To complete the automatic weld square and round fuel tank. Tank length: 400-1500mm.

2.Fuel tank material: mid steel, aluminum

I. Design Mission

1.To complete the automatic weld square and round fuel tank. Tank length: 400-1500mm.

2.Fuel tank material: mid steel, aluminum

3.The welding seam appearance is good and smooth. It is convenient and reliable to use machine.

4.MIG welding

5.Machine can work continuously for 24-hour.

III. Design Conception

1. Welding torch moves up-down, forward-backward to coordinate with workpiece rotation.

2. CNC system to control 3-dimension actions

3. Rotation speed is varying with the workpiece rotation position, to make sure the welding linear speed is the same.

4. PLC and CNC system to control the above process, and improve the reliability.

5. Two welding torch can improve efficiency and reduce the deformation.

IV.Equipment Structure

Equipment consists of machine body, protective cover, fixture, rotary axis power mechanism, workpiece vertical CNC travelling mechanism, workpiece forward and backward CNC travelling mechanism, welding torch adjustment mechanism, CNC control system, electrical control system, welding power source and other components.

V. Work Process

manual loading → lift the workpiece → clamp the workpiece → rapidly move the welding torch to welding position →supply the Argon gas→ arc igniting → Welding → Welding torch moves up and down, forwards and backwards, weld the first circular arc → rotate the rotary axis by 90°, at the same time, the welding torch quickly moves up and down , forwards and backwards, welds fillet→ torch walks up and down, forwards and backwards, welding the second circular arc → rotary axis rotates 90°, at the same time, the welding torch moves up and down, forwards and backwards, welding the fourth fillet → arc ending → stop Argon gas → release workpiece → bracket falls →manual unloading

.jpg)